Positive Graphite Market Demand Forecasts

Global demand for graphite is being fuelled by rapidly growing interest in the electric vehicle (EV) and energy storage industry. Reports from World Bank’s ‘Minerals for Climate Action: The Mineral Intensity of the Clean Energy Transition’ publication indicate that high-impact minerals such as graphite will have to see a significant production increase to meet the demand that is stemming from this renewable energy market.

Currently China produces up to 70% of the worlds natural graphite and both the EU and the United States have placed Graphite on their critical raw mineral materials list that are considered to be in supply risk. Walkabout is a member of the European Raw Material Alliance (ERMA) which aims to diversify and secure raw materials sourcing from third countries and remove distortions to international trade, fully respecting the EU’s international obligations.

Materials derived from recent Benchmark Mineral intelligence reporting demonstrate the upward trend in demand for graphite in coming years. This level of demand is predicted to outstrip supply by 2023.

Graphite Varieties

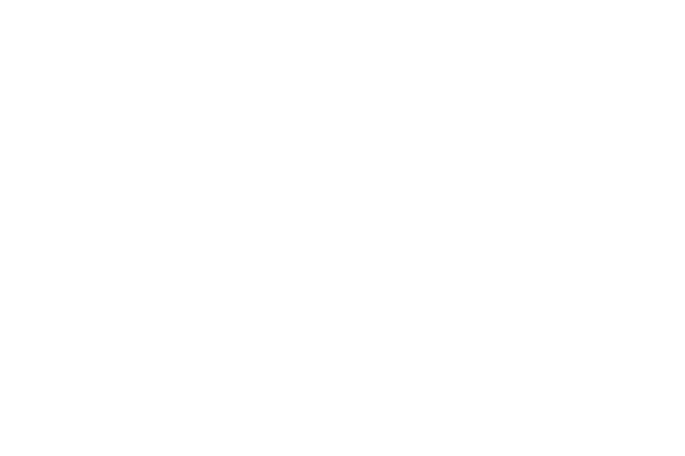

Flake Graphite - Lindi Jumbo

Flake graphite (also known as crystalline graphite) has a distinctive platy appearance, formed when pure carbon atoms “stick” together to form flat sheets. It is less common than amorphous graphite, has a higher purity and is priced significantly higher. No two graphite deposits are the same, and the physical and chemical properties of flake graphite from each source (i.e. from each graphite mine) are unique and represent a flake graphite ‘signature’. Lindi Jumbo will be mined for its Jumbo Flake Graphite upon entering production.

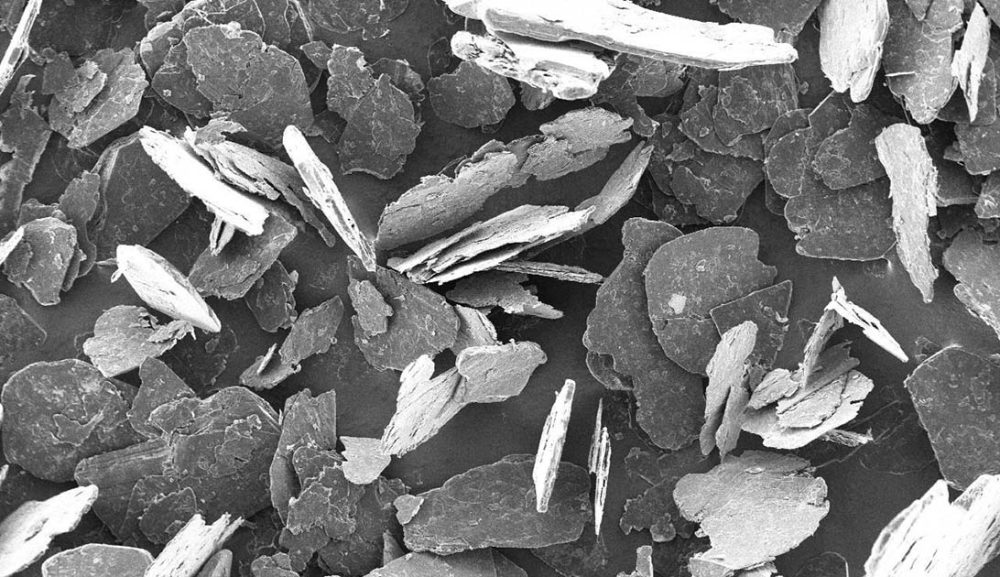

Amorphous Graphite

Amorphous graphite (small crystal size or microcrystalline) is the most abundant form of natural graphite but has the lowest quality and has a lower carbon content than natural flake graphite. It is a low-priced graphite product that cannot be upgraded through flotation or purification and is limited in its usage.

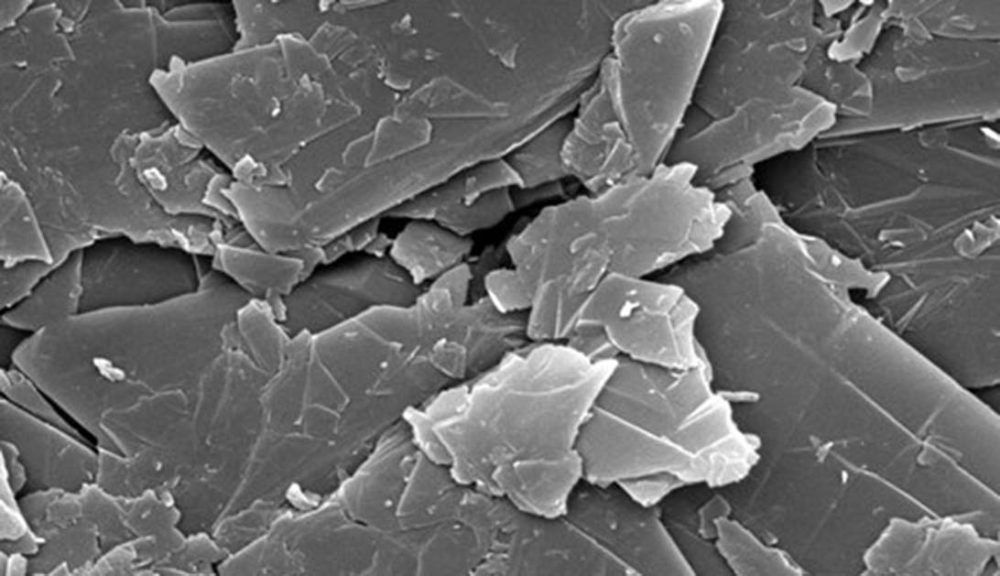

Vein Graphite

Vein graphite is the most scarce form of graphite, has a carbon content of 90-99% and is currently only commercially extracted in Sri Lanka. Because of the high cost and scarcity of this graphite variety, its application in the market is very specialised and limited.

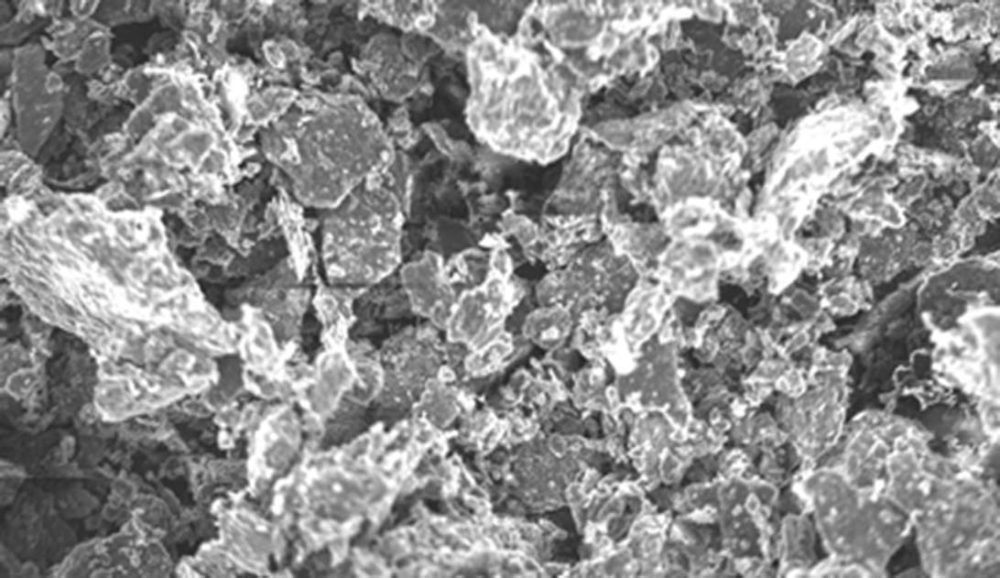

Expandable Graphite

Expandable flake graphite is what the graphite product is known as after it has undergone a process of intercalation whereby an intercalant material is inserted between the graphene layers of a graphite flake. The intercalant may affect both the physical and chemical properties of the flake, including crystallographic structure, surface area, density, electronic properties, intumescent behaviour, chemical reactivity, etc.

The simplified process could be by treating highly crystalline natural flake graphite with a mixture of sulfuric acid and certain other oxidizing agents which aid in “catalysis” of the sulphate intercalation and the prime reason for the intercalation process is to impart the ability of the treated flake graphite to intumesce, exfoliate, or expand when heated.

The exfoliation of the expandable flake graphite results in an overall decrease in bulk density, and an large increase in surface area. Not all intercalated graphite expands equally and differences in in treatment type (intercalant), particle size, etc., all have a bearing on the overall expansion of the product.

Applications of Expandable Graphite

- Fire retardants

- High-performance gaskets

- Conductive fillers

- Electromagnetic pulse and radiation shielding

- Foundry products

- Battery systems

- Coatings and plastic foils

- Rubber products e.g. conveyer belts

- Manufacturing graphite foils

- Heating and cooling systems

- Energy storage systems

- Sealing systems

- High temperature applications

- Graphene

Advantages of Expandable Graphite

- Excellent flame retardant effect with low material use

- Reduces fume formation

- Free of heavy metals

- Non-polluting Halogen free (not harmful to health)

- Chemically inert

- Corrosion resistant

- Excellent electrical and thermal conductivity

- Flexible Heat resistant

- Oxidation resistant

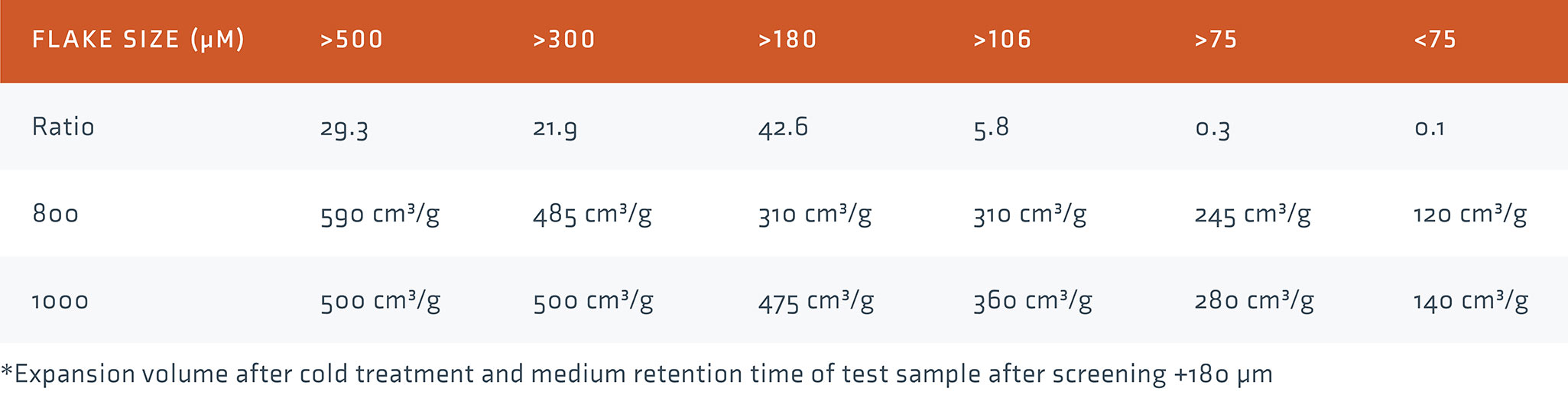

Screened sample ratio - 800°, 1000°

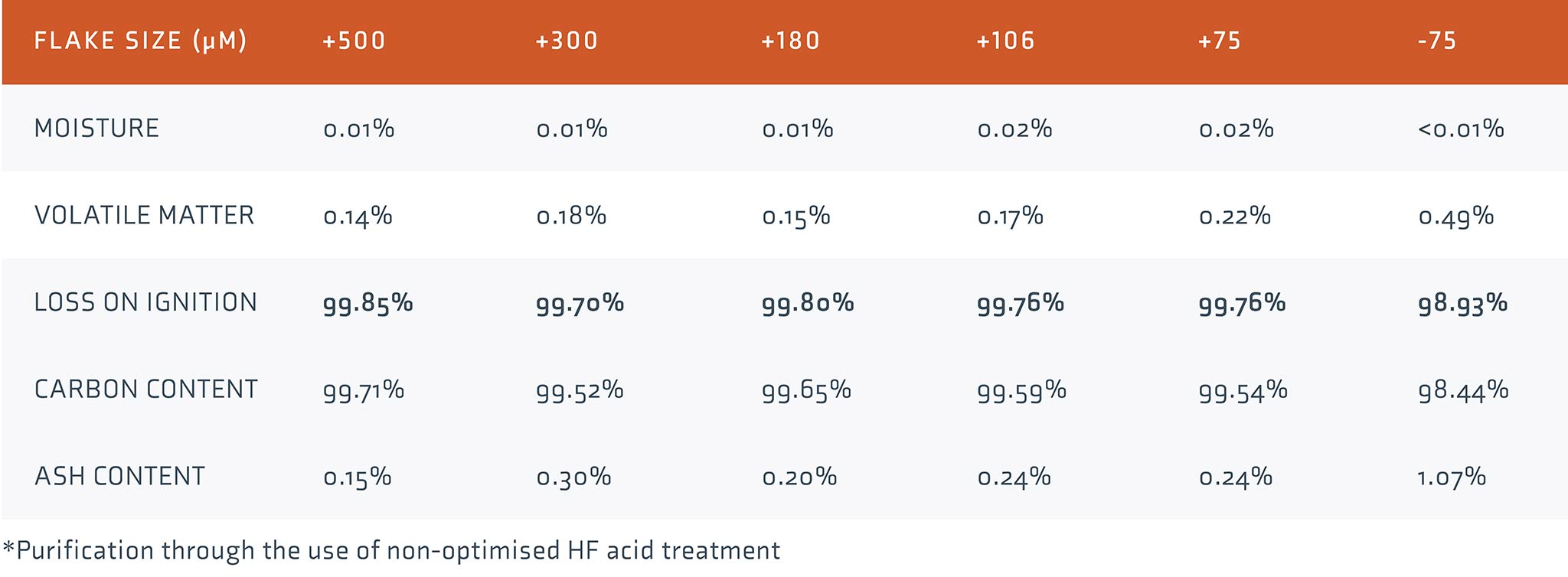

Lindi Jumbo High Purity Graphite Specifications

Characteristics of Graphite

Electric Conductivity

- 100 times higher conductivity than other non-metallic minerals with conductivity

- Thermal conductivity is higher than that of steel, lead, zinc and other metal materials,

- Thermal conductivity decreases with the increase of temperature, serving as an excellent insulator in high temperatures.

High Temperature Resistance

- Melting point of graphite is 3 927°C;

- Boiling point of graphite is 4 250°C.

Chemical Stability

Chemically inert and resistant to acid, alkali and organic solvents.

Hydrophobicity

Has air permeability and is naturally hydrophobic.

Lubricity

Has good lubricity, especially larger flake graphite. The larger the flake, the smaller the friction coefficient, resulting in better lubrication performance.

High Strength

Graphite’s strength is very high, and is strengthened with the increase of temperature. At 2000°C, the strength of graphite is doubled.

Graphite Form vs. Application

While graphite comes in three distinct forms, the main form of graphite set to be mined at the Lindi Jumbo project site is Flake Graphite; predominantly Large Flake and Jumbo Flake – estimated to make up to 75% of total production in the 24-year LoM.

Broadly speaking, the following traditional markets for flake graphite are:

Writing Materials

Well known for its use as the “lead” in pencils.

Steel and Casting Materials

Graphite is commonly used as a carburizing agent in the steel- making industry and used as a mould coating in the casting industry.

High temperature resistant friction materials and lubricants

Used as a wear-resistant and lubricating material for mechanical equipment, which can allow sliding at speeds of up to 100 metres / second in the temperature range of – 200 ~ 2,000°C, with little or no use of lubricating oil. As such, it’s ideal for use in car brakes and clutches.

Repellents

Used in paint where the water repellent properties provide a protective coating on the painted surfaces.

Nuclear industry and national defence

- Used as a neutron decelerant for nuclear reactors.

- Used in the national defence industry to make solid fuel rocket nozzles, missile nose cones, aerospace equipment parts, heat insulation materials and anti-radiation materials.

Refractories

- Used to make graphite crucibles.

- As an ingot protective agent, to produce magnesia carbon brick, alumina magnesia carbon brick and other lining materials.

- Used in the production of glass and steel as well as the processing of iron.

Conductive materials

- Used to produce electrodes, brushes, rods, carbon tubes and coatings for TV picture tubes.

- Used for the production of ordinary batteries, alkaline batteries, fuel cells and batteries (including rechargeable batteries).

Traditional printing toner materials

- Good carbon paint.

- Deep processing of natural graphite can maximise its superior conductivity and adsorption properties, and produce high-quality printer toner.

Chemical industry

- Used in the production of heat exchangers, reaction tanks, condensers, combustion towers, absorption towers, coolers, heaters, filters, pumps and other equipment.

Environmental protection industry

- Expanded graphite has super large adsorption capacity for oil and macromolecular organic matter in water.

- Widely used in the fields of offshore oil leakage and oilfield wastewater treatment.

Safety industry

- Expanded graphite used as a flame retardant.

- Used as an active char forming fire retardant in non-structural polymers and coatings.